Clean the oceans

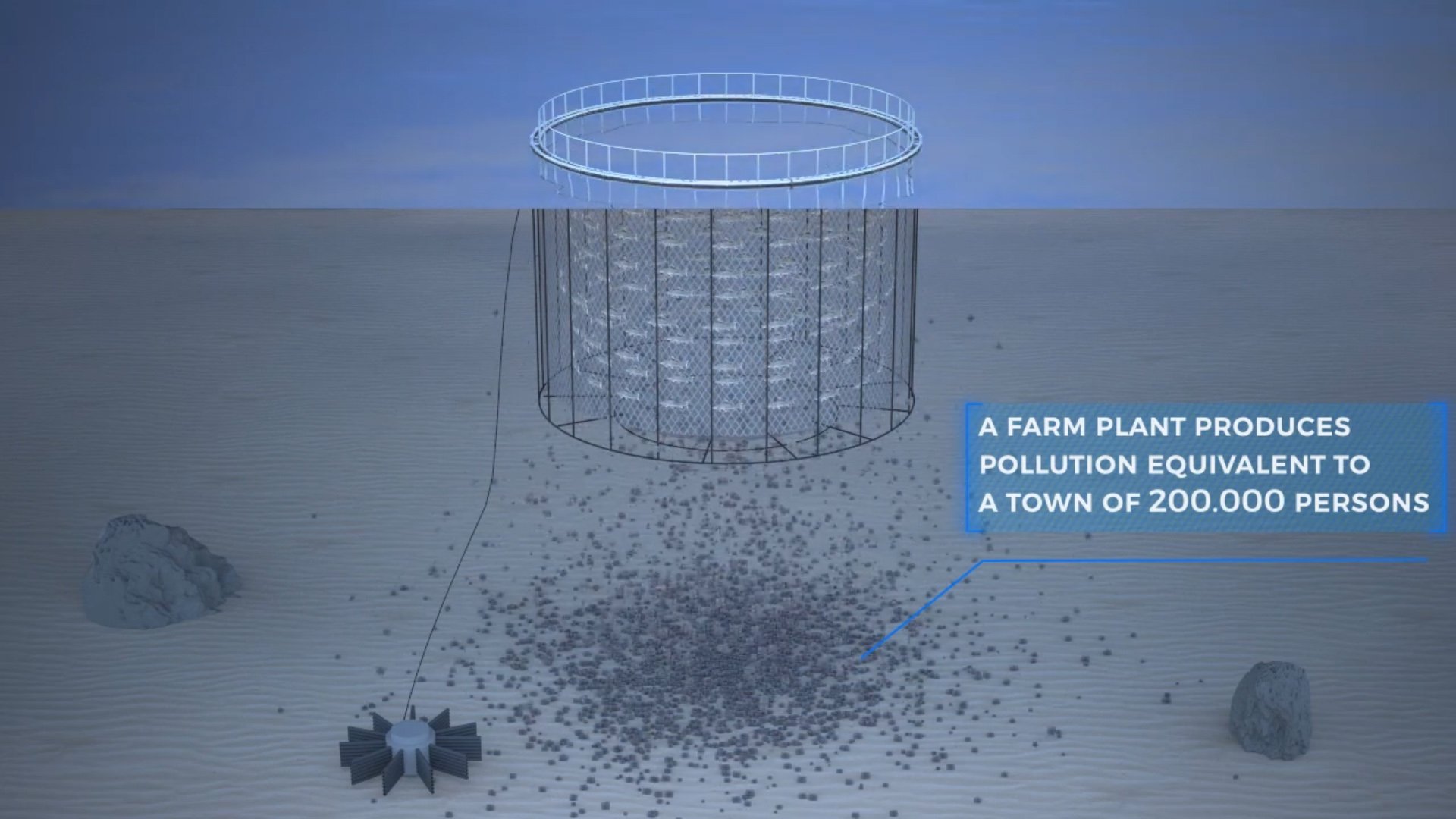

Waste, Oil and Pollution Removal. Remote cleaning underwater for the seabed.

Suitable for shallow or deep operations in sea, lakes, rivers and reservoirs.

Building relationships and partnerships with our customers is important to us.

When you ask, we make suggestions for solutions.

When you have a specific need or requirement, we provide solutions.

How it works

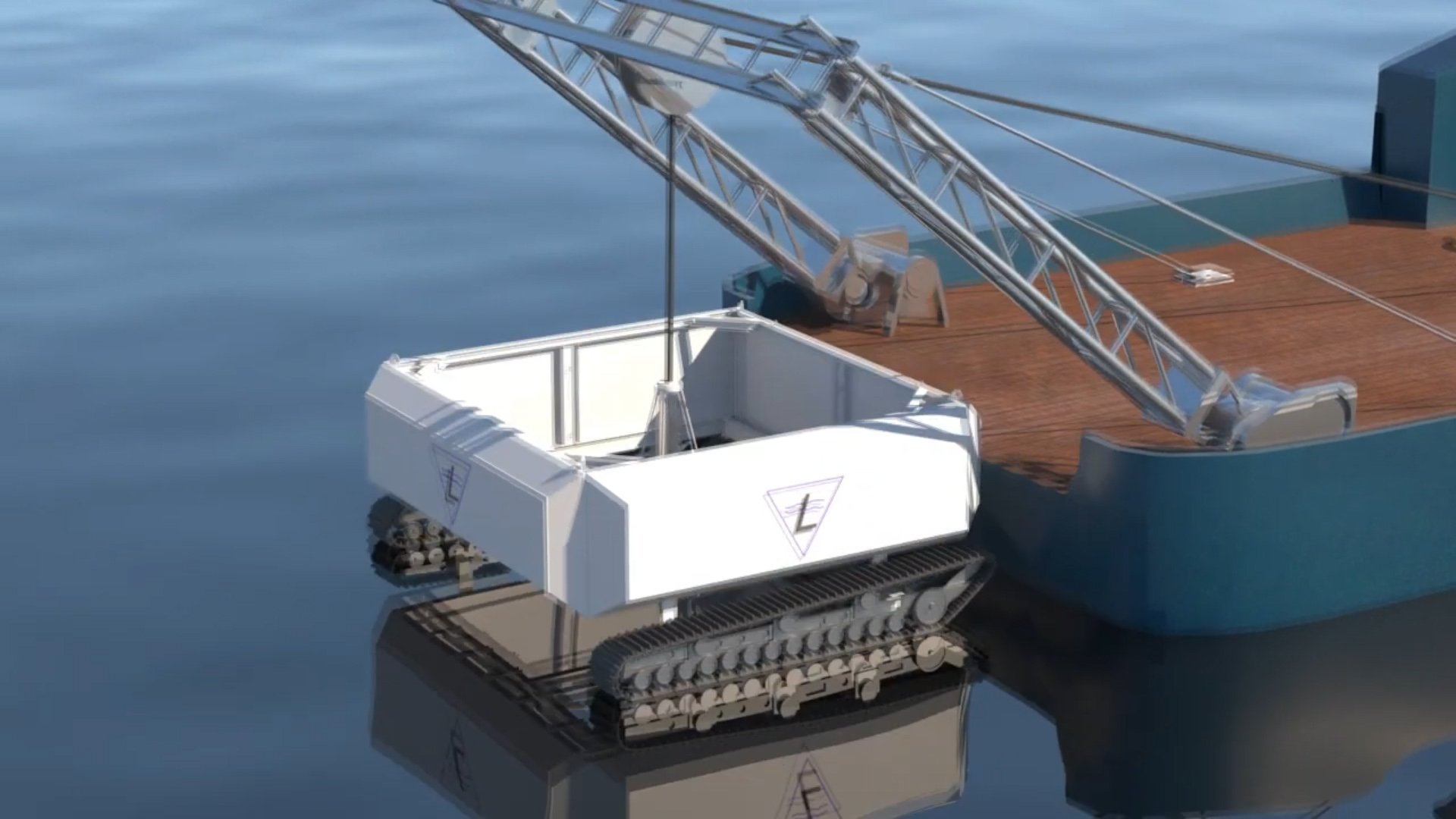

Cleaning Seabed Service - SAAS System

Waste, oil and Pollution Removal. Remote cleaning underwater. Suitable for shallow or deep operations in sea, lakes, rivers and reservoirs.

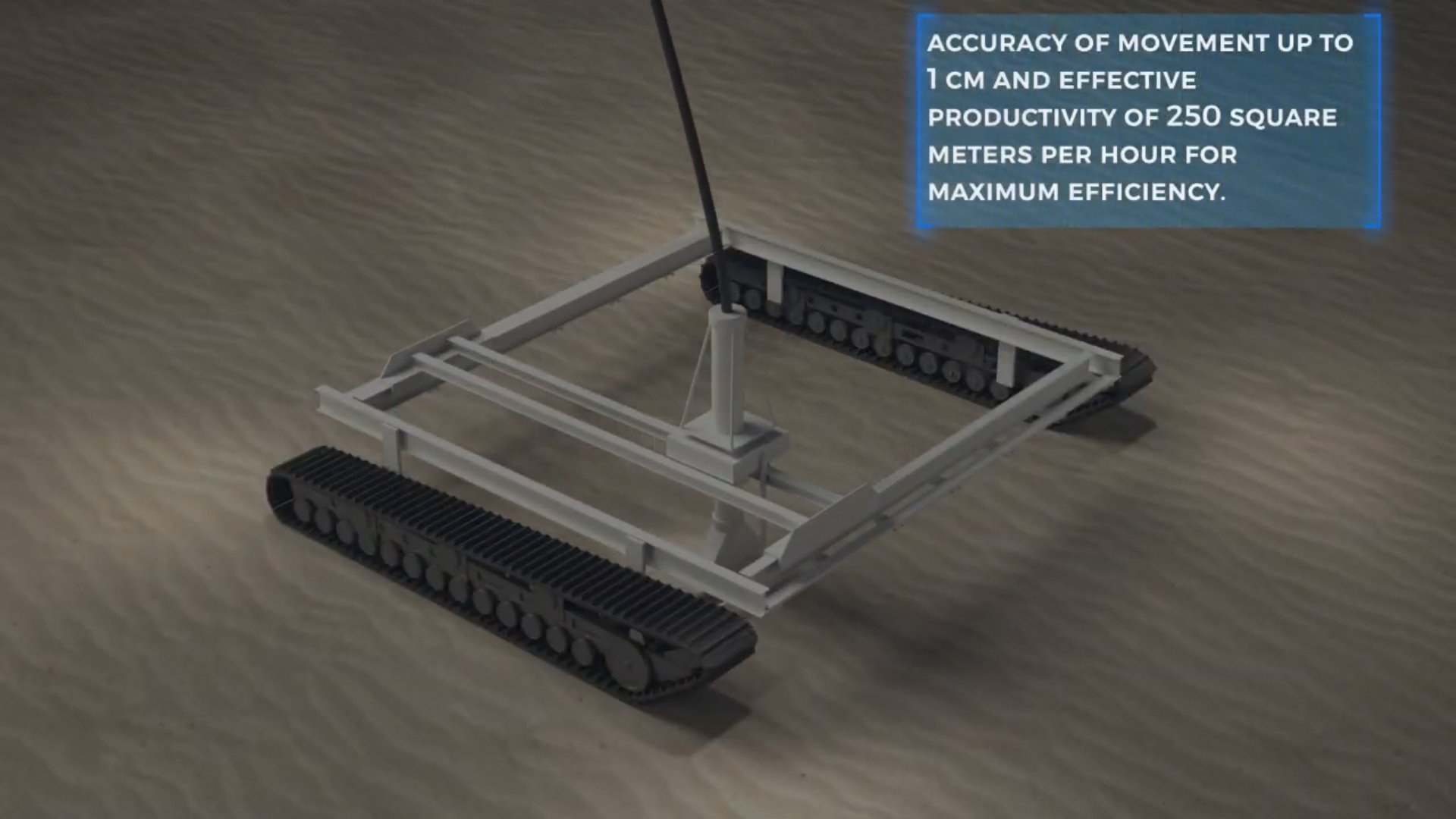

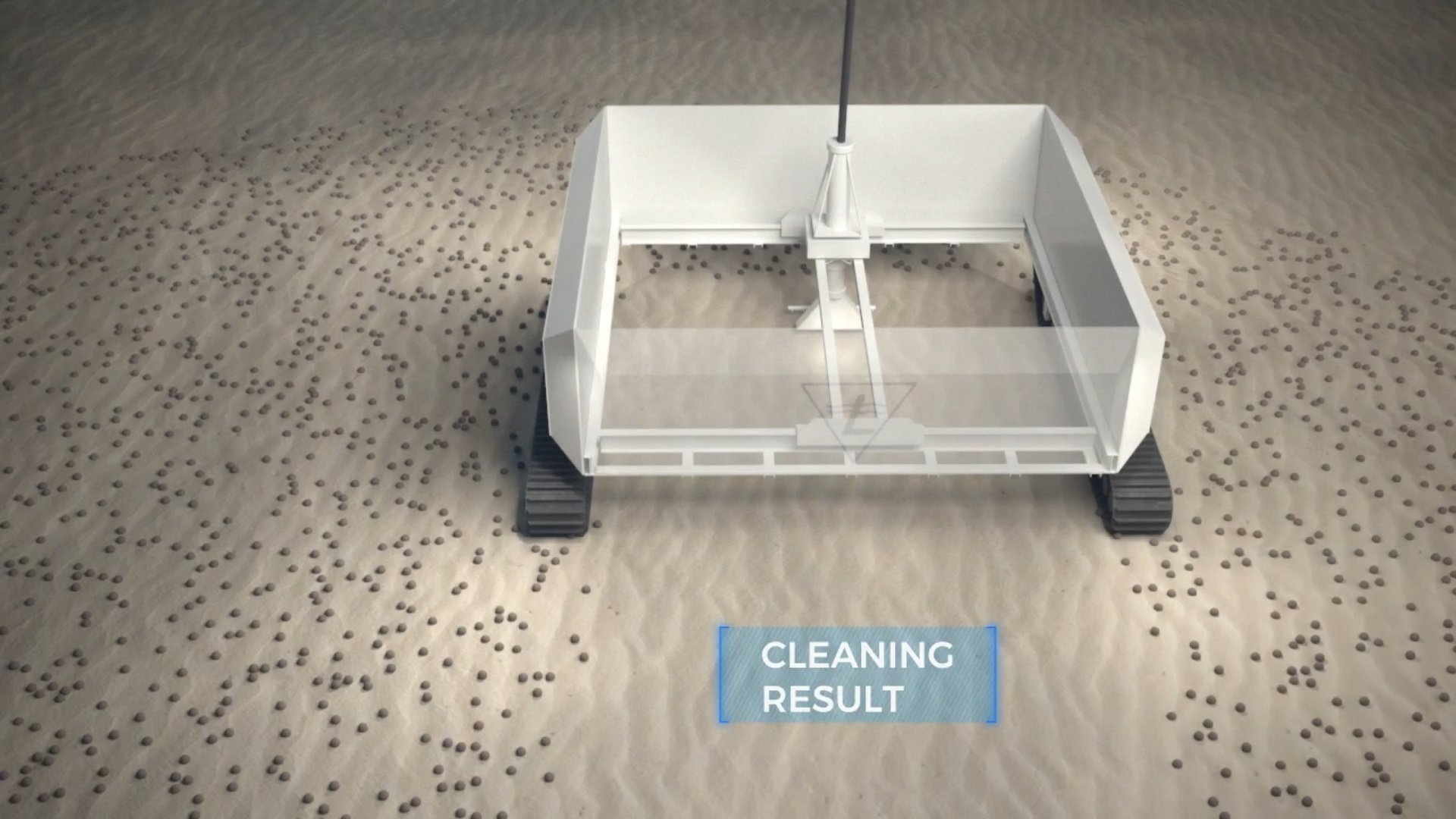

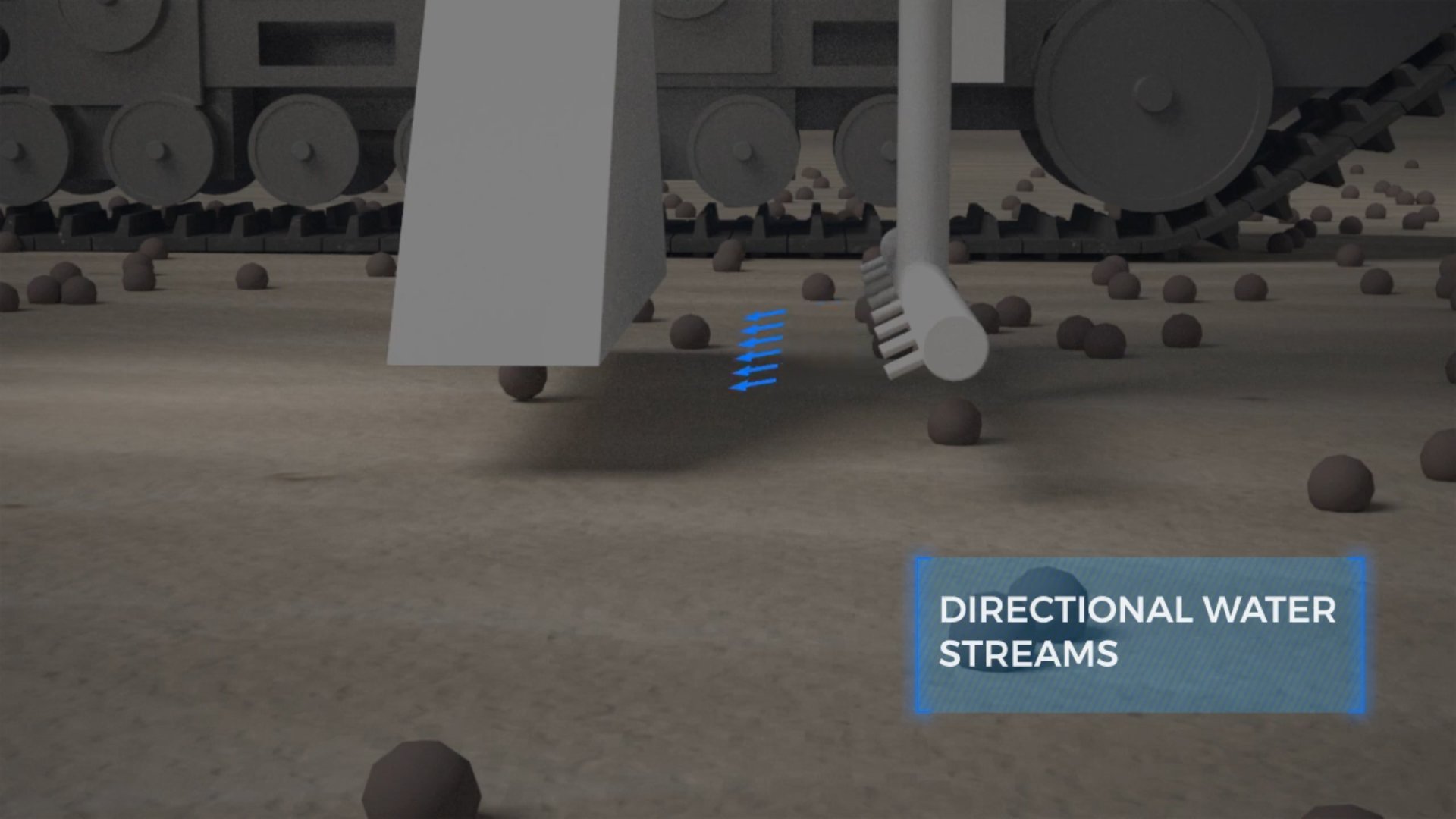

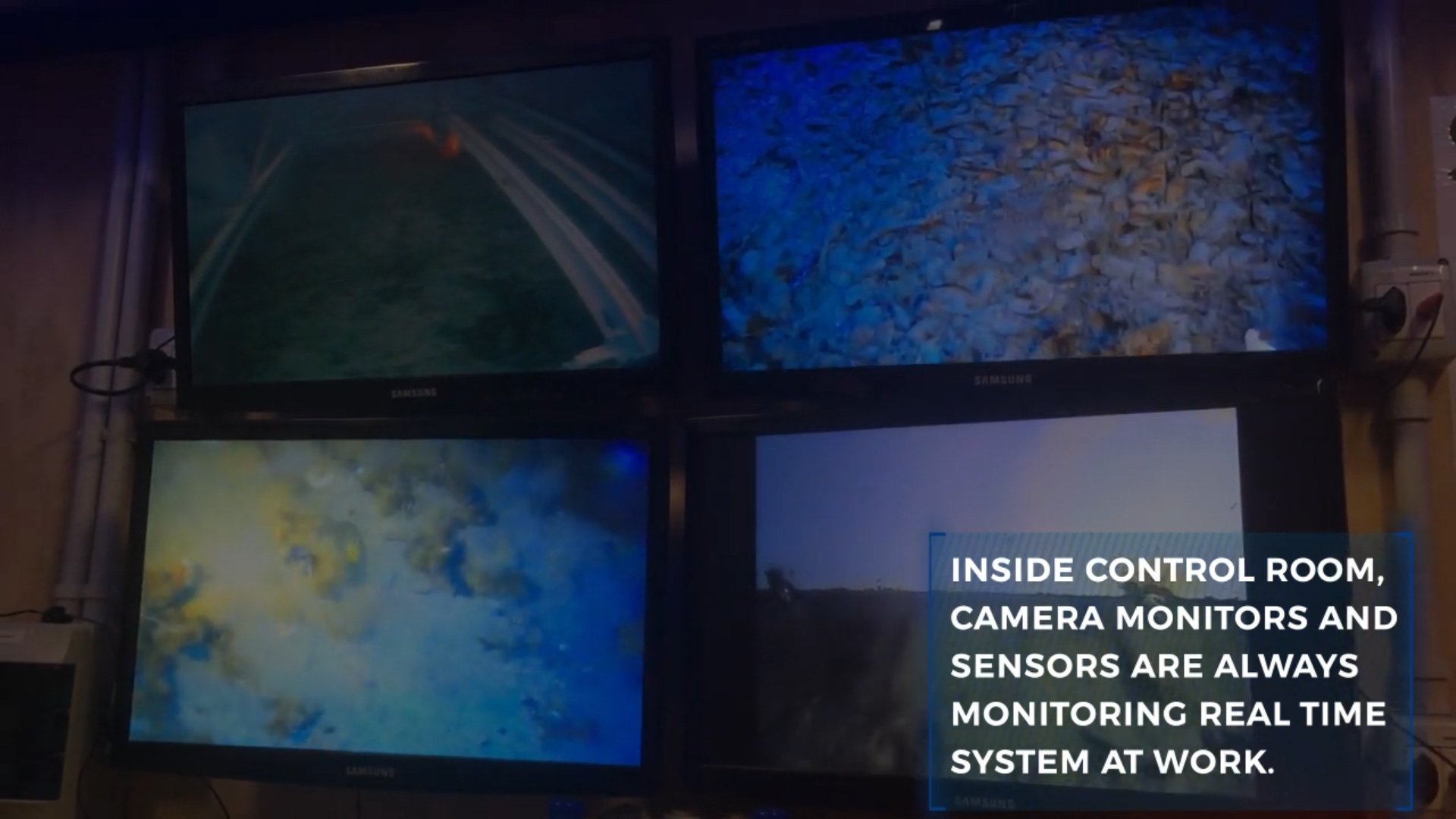

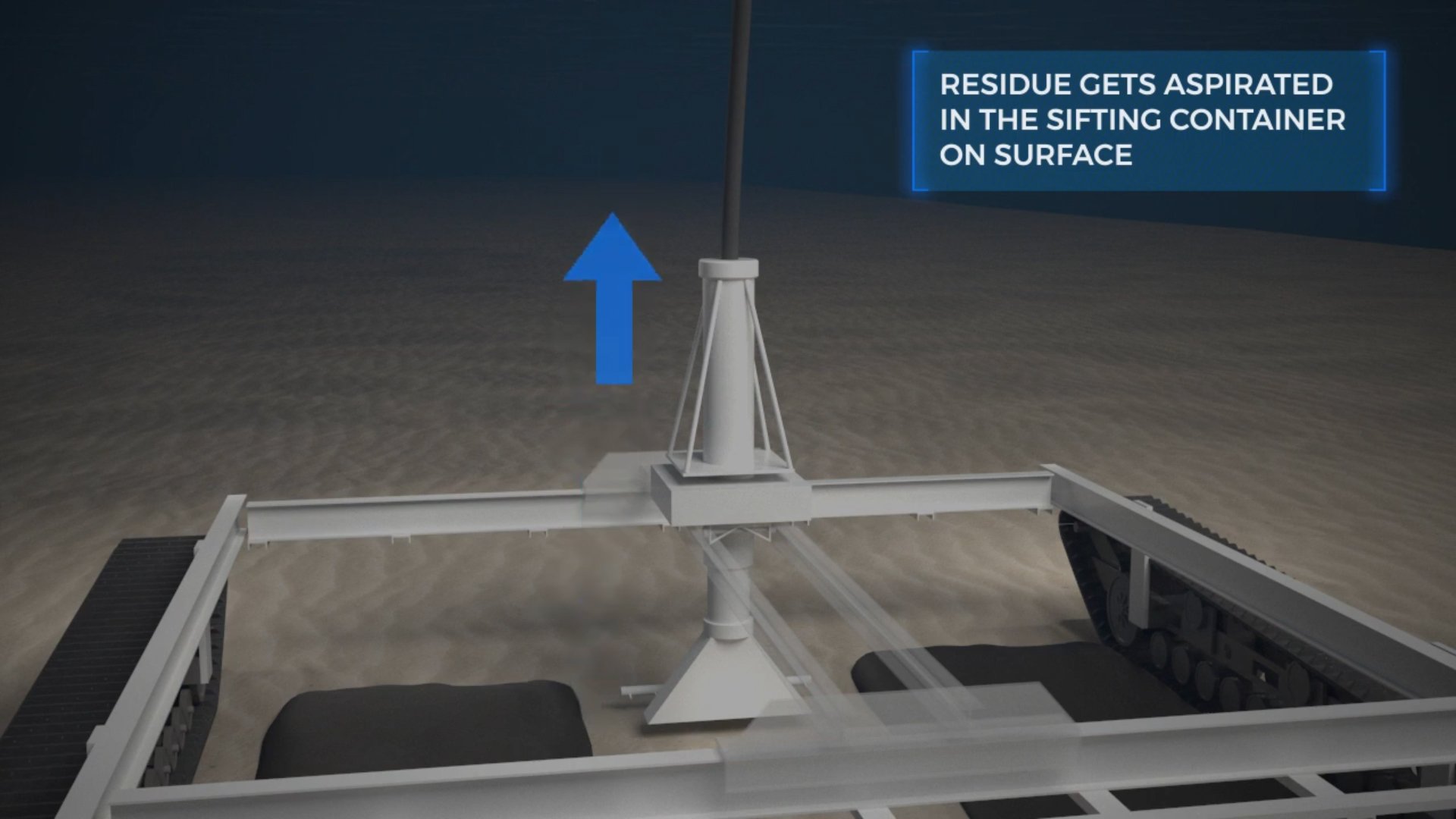

Tracked Vehicle that is piloted by technician and use of suction pump to remove all materials that needs to be treated from seabed. It has a full directional pumping system with sensors and Cameras and if needed, it can be equipped with special shredder in order to reduce debris measure.

Saas Can clean up to 500 sq mt of seafloor X Hour

Pump is sized in according with necessity. (from 1000 to 4000 cubic x Hour)

Debris screening & sifting compartment:

Divides all upcoming materials in 3 sizes :

Bigger then 5 mm (Not soil material go to debris collector)

(Soil material go to regulator Mill to be reduced between 5mm and 0,1 mm)

Between 5mm and 0,1 mm (go to Low Heating Treatment)

Smaller 0,1 mm with water is checked for Heavy Metals Presence

Dewatering Compartment

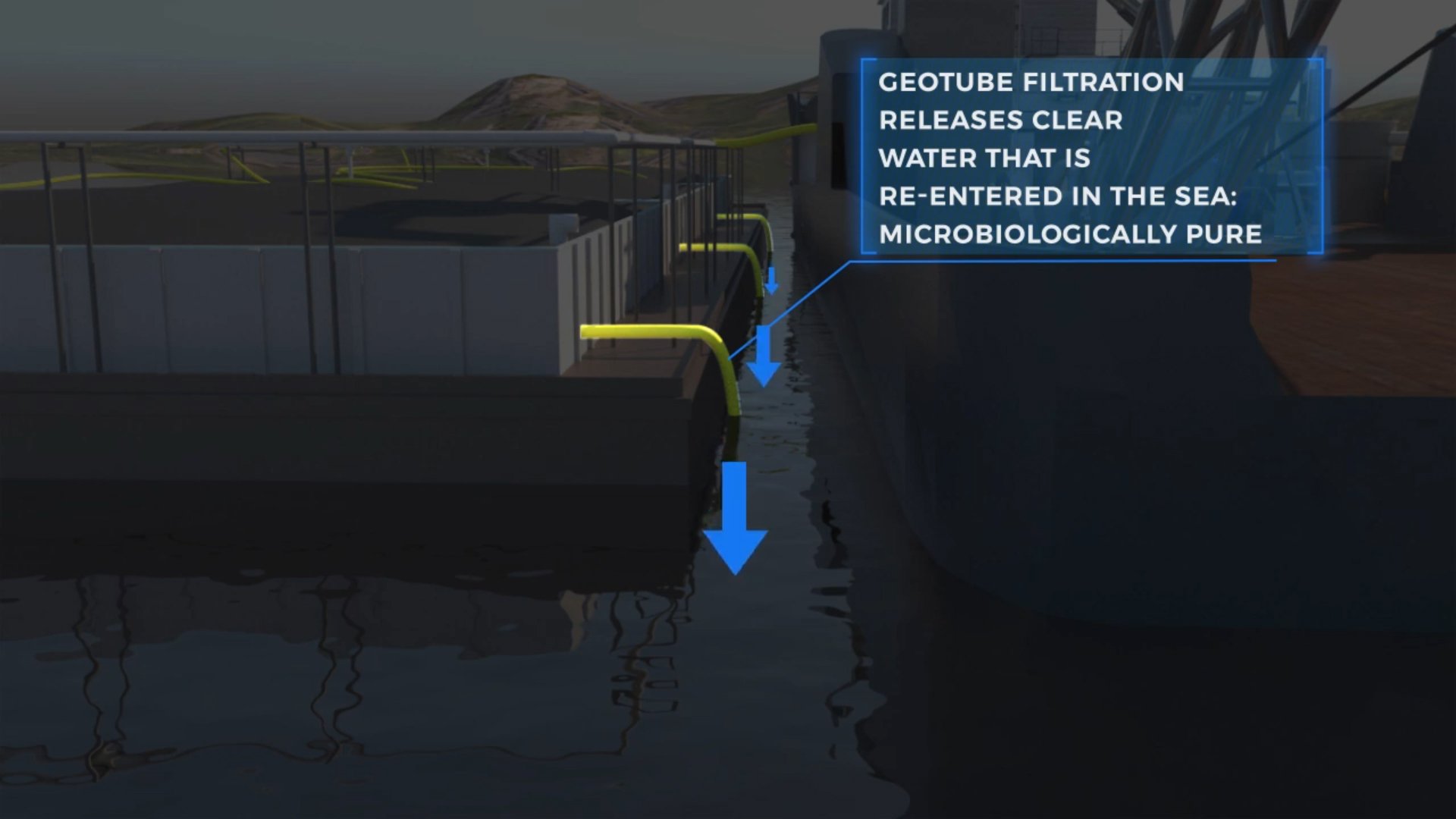

Material < 0,1 mm without Heavy Metals is de-watered and cleaned from the most part of oils. Water pass inside oil removal filter and return to sea.

Material < 0,1mm with heavy metals will be treated with chemicals and Active carbons.

Material < 0,1 mm without Heavy Metals is sent for dewatering and cleaned from the most part of oils. Water pass inside oil removal filter and return to sea.

If there is no presence of Heavy metals in the second Control station then material moving to Low Heating Compartment.

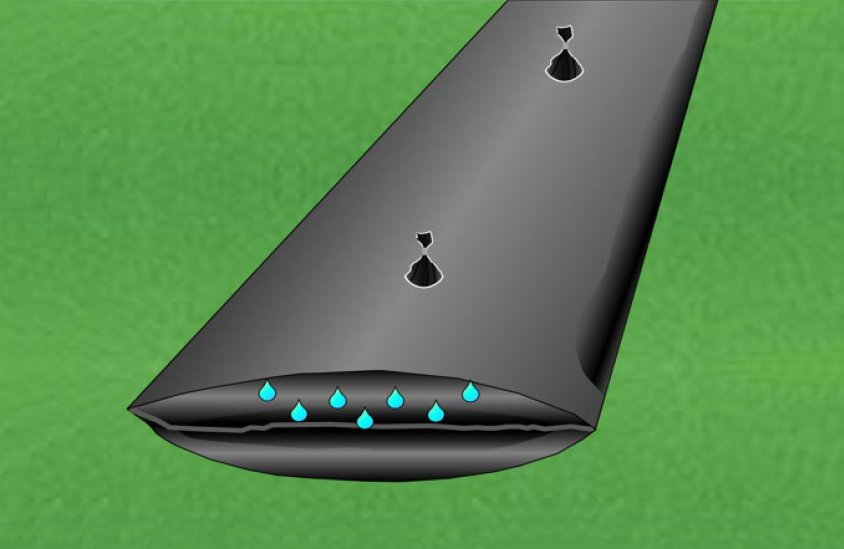

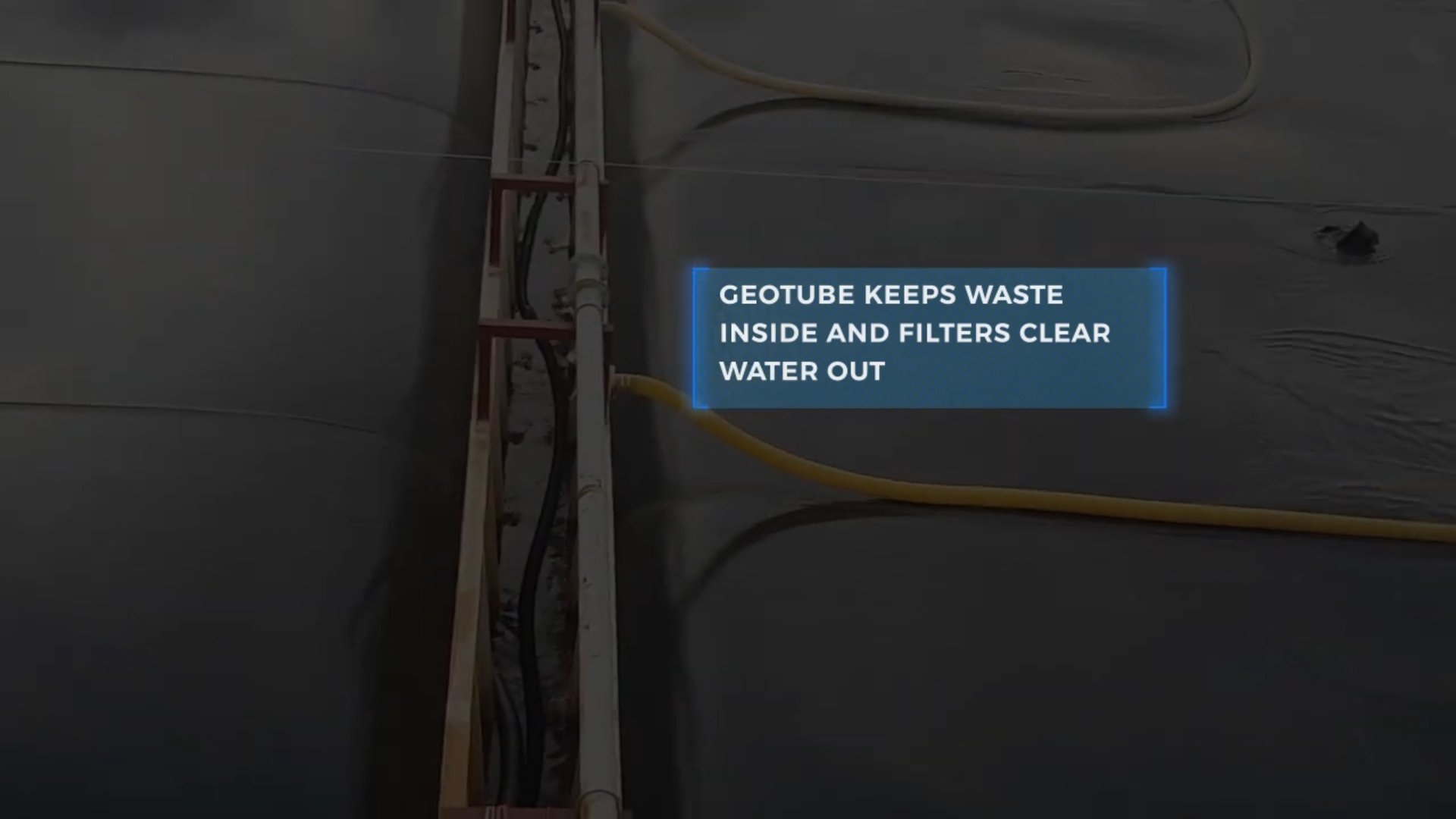

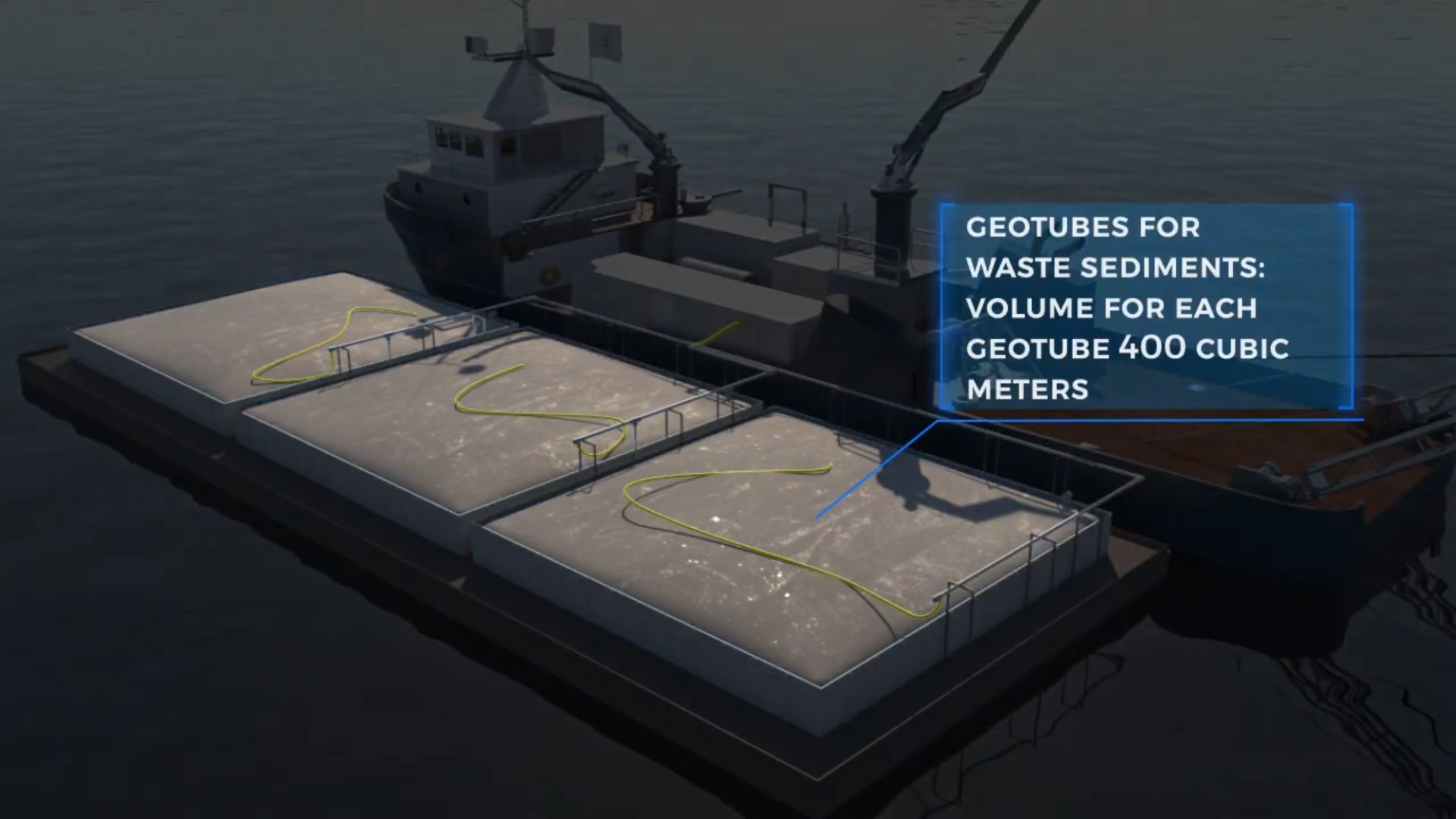

Geotube dewatering on working

Geotube 450 M3 volume on working. Each geotube has 600 tons of dryied sediments storage capacity.

The capacity in blank situation is 36 liters/second per square meter of surface.

Make Things Happen

Thinking and planning is good if it leads to action closer to now than tomorrow.

Oil contaminated treatment

Tubular Geofilters (TGs) Dewatering Technology

Tubular Geofilters

Tubular Geofilters (TGs) for dewatering are realized with high tensile strength, high permeability and high chemical resistance geotextiles, and very high tensile strength seams.

They are filled with sludge to obtain an efficient and economic dewatering. Tubular Geofilter are realized with high resistance multiple seam, to ensure at least 80% of geotextile tensile strength, this is necessary to let TGs to resist pressure during the sludge pumping operation.

Each Tubular Geofilter can contain up to 2400 m3 of sludge and it can be filled in few hours (time usually depend on pump flow instead to the limits of technology as usually happens with traditional technologies (such as filter press, belt press, etc..). Tubular Geofilters can be used in every works from the small to the biggest one and with any kind of sludge, they also let you to work both in batch or in continuous, as you prefer or need.

Furthermore, because Tubular Geofilters haven't got any mechanical or electric parts they have both a low value of energy consumption (only due to sludge pumping operations) and a very high reliability and requires very very less maintenance. The dewatering process can take more than 1 month to be accomplished (depending on different parameters like initial and final content of sludge's dry matter, kind of sludge, kind of chemicals used, etc..) but after that the sludge within the Tubular Geofilters can be easily removed by bulldozer and then can be switched to reuse or to further treatments (e.g., thermal drying, etc..).

In addiction TGs dewatering treatment don't need any preliminary treatment (except the dosage of chemicals and, in some cases) and let you to make a lot of treatments (if you want or need to do it) both on dewatered sludge and (e.g. thermal drying, etc..) and on filtrate (e.g. oils-water separation, chemical or biological treatment, etc..).

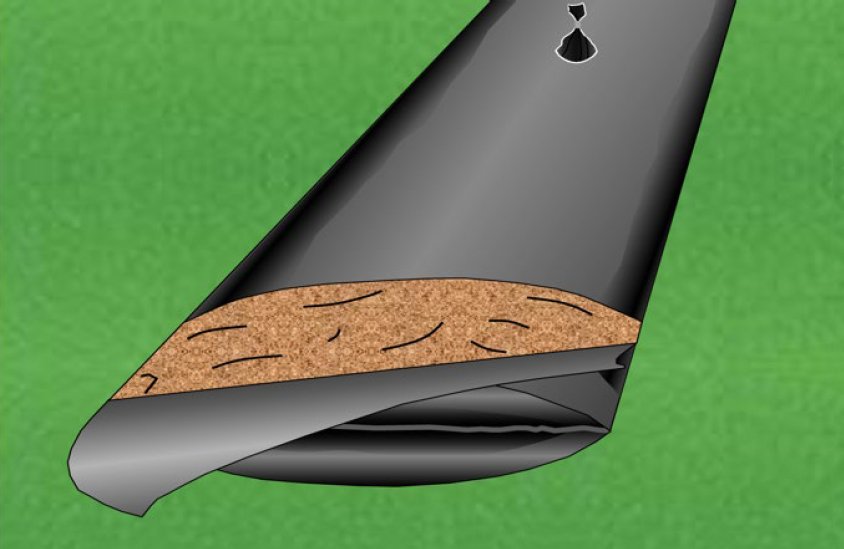

How it works

Tubular Geofilter is filled, by pumping, with the sludge (liquid);

to improve the aggregation of the smallest solid particles, and so its separation from the liquid phase, one or more chemicals (depending of the concentration and nature of solid particles itself) have added into the sludge and mixed with it before to reach the TG.

The free water portion

(after the separation due to chemicals dosage) pass through the Tubular Geofilter 's geotextile surface while the solid particles are blocked and retained within it. TG can block more than 99% of solid particles and so the resulting liquid outlet is very clear and usually need only a simple treatment.

After that the free liquid portion

in this step there is the drainage of the pore water through consolidation mechanism. In this way the dry matter content of the sludge into the Tubular Geofilter increase till it will reach a solid consistence. The total volume reduction is more than 80%, while the solid dry matter content is more than 25%.

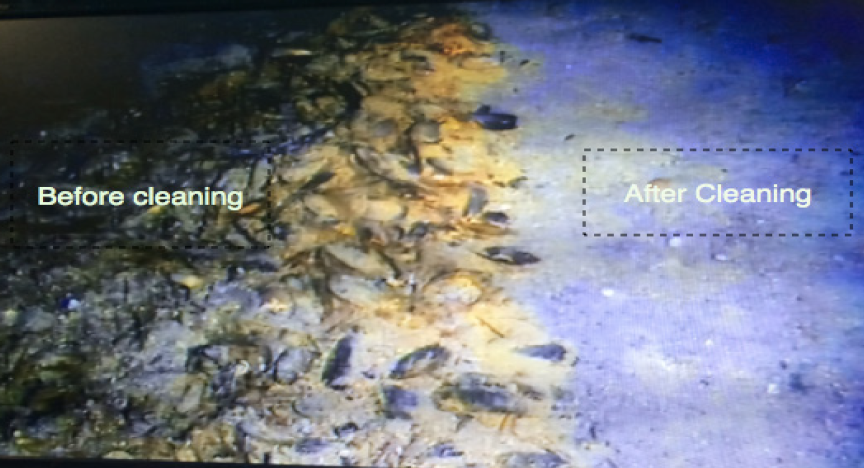

In this picture

you can see the efficacy of the dewatering process with Tubular Geofilter; on the left there is the sludge (from wastewater treatment plant) to dewater (before the addiction of the chemicals) while on the right there is the liquid outlet of dewatering process.

As you can see the liquid is very clean and clear; in this case the filtration efficiency (the total amount of the solid particles blocked into the Tubular Geofilter) was greater than 99.9%.

Sample that shows the early results of Oil drilling

muds dewatering treatment with TGs

Sustainable

“Meeting the needs of the present without compromising the ability of future generations to meet their own needs.”

True sustainability is when everyone, everywhere can meet their basic needs forever.

The Brundtland Commission officially dissolved in 1987 after releasing Our Common Future, also known as the Brundtland Report. The document popularized the term "sustainable development" and won the Grawemeyer Award in 1991.